air handling unit bms

Building Management Systems (BMS or BEMS) are essential to effective energy management and if any one piece of equipment, or its control, goes wrong it can cost a fortune – and this can go undetected for many years. Unfortunately, there are many ways in which things can “go wrong” and, unless your operators are well trained and careful, your BMS will be wasting a lot of energy. Even organisations that employ full time BMS engineers, or have expensive “energy efficiency” BMS maintenance contracts, frequently have seriously dysfunctional systems. This issue of Intelligent Energy Insights considers many of the ways that you can improve the energy efficiency of plant controlled by your BMS and covers the following topics. You might also like to consult the related edition of Insights: Managing Energy for Comfort Click here to see all Intelligent Energy Insight topics A high level of control over plant and equipment is a fundamental pre-requisite for the minimisation of energy use.

This control is often achieved by a BMS and the optimisation of these is extremely important. A well specified, installed, maintained and operated BMS will achieve huge savings compared with a less well executed example. This becomes clear when typical consumptions figures are considered. A large site may have boiler plant rated in megawatts, with hundreds of kilowatts of cooling capacity. A single heater or chiller battery in an air-handling unit may well be rated at over 100 kW. Some sites require humidification, and often electric humidifiers are installed, some of these being rated at over 50 kW, perhaps costing £5/hour to operate in electricity alone. This is a basic function of a BMS but it is surprising how often it goes wrong. A recent Green Consultancy BMS Health Check identified plant that was enabled from five-past midnight when it should have been five o’clock in the morning! Time schedules should be checked in conjunction with building operators, and plant operation minimised wherever possible.

The number of separate schedules should also be minimised. For example, each fan-coil unit does not need its own schedule. Optimum-start is often misunderstood and can result in plant coming on hours before it is required. Some people describe a BMS as a “big time clock”. In a depressingly large number of cases they do not even achieve that. Heating circuit temperatures are usually too high, resulting in additional energy use and raising the temperature within the building, whatever the emitters are doing.

pop up camper ac braceWeather compensation should be used to minimise circuit temperatures, and even constant temperature circuits may be “turned down” during spring and autumn, if they are required at all.

hvac roof curb cad detailsChilled water should be circulated at as high a temperature as possible, commensurate with the achievement of sufficient cooling.

2002 nissan sentra ac control unit

In many buildings, particularly modern ones, space temperatures are far too high. It may be worth reminding occupants that the air temperature is only one of the factors that affect their perception of temperature. Humidity is at least as important, together with air-movement, the radiant heat balance, what you are wearing and what you are doing. Many space heating problems could be resolved simply by reducing temperatures and encouraging staff to wear appropriate clothing, although such suggestions are not always well received. (The surprisingly complex issue of temperature perception will be the subject of another edition of Insights). These apply to both plant and space temperatures. The BMS often demands LPHW temperatures that the boiler plant is unable to achieve, and this will result in serious boiler control problems. Similar considerations apply to chilled water. Space temperature set-points as high as 30oC or as low as 12oC are often seen on clients’ BMS. This is usually the result of the plant failing to achieve a more sensible temperature, complaints of over-heating or cooling, and a knee-jerk reaction: adjust the set point.

There may be occasions when the sensor is out of calibration or poorly located and, if this is the case, then it should be rectified instead of using set-points, which if achieved, would result in considerable discomfort and the use of excessive energy. Nearly all weather compensation is set to “standard” conditions: a flow of 80oC at zero ambient and 20oC (or more!) at 20oC ambient. These settings might be appropriate for Victorian asylums but they result in overheating in modern, well insulated buildings that also have considerable internal gains from lighting, IT, vending machines etc. Ideally, a heat-loss calculation should be completed for each building and the “base” temperatures for heating and cooling established. These should then inform not only the weather compensation settings but also “eco-off” and other set-points as well. Ideally, there should be a deadband between the set-points for heating and cooling preventing simultaneous operation. This is potentially achievable in many buildings, but rarely achieved in practice.

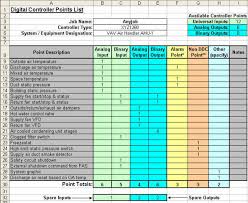

This tends to be inadequate, and reduces the effectiveness of the BMS for both control and maintenance activities. For example, an air-handling unit of any size should incorporate sufficient temperature sensors to identify the operation of each of the heater and chiller batteries, heat recovery etc. Simple logic checks will then identify any control aberrations or failures that might warrant further investigation. If a heater battery can dissipate 100-kW or more, the mal-operation of a control valve could result in additional expenditure of >£10K/year, and this will double if cooling is applied in order to correct the failure. Good schematics will allow even unskilled operators to rapidly gain an understanding of what is going on. Unfortunately, there are often major errors that are misleading and very bad for effective control. Often, plant is missing or incorrectly presented, whilst basic information on control loops etc is notable by its absence. Does your BMS actually reflect what is in the plant room?

Similarly, when there are multiple items of plant which are all the same it is much better to have a single generic schematic, with the information and set-points for each individual item included in a matrix. This vastly improves access to the information and the likelihood of identifying aberrant operation. Whilst the BMS should produce a high standard of plant control, M&T can check that it is actually achieving it. First stop must be the charting function included within many BMS. Circuit and space temperature charts provide an invaluable insight into plant operation, and can frequently identify anomalous operation. Use may also be made of the site’s half-hourly data. It is clear from the above that a thorough investigation of the set up and maintenance of your BMS, and the plant that it controls, is likely to reveal significant energy savings opportunities with fast paybacks. To ensure that the energy consumption of your boilers and associated equipment is minimised we suggest a Green Consultancy Boiler Health Check.

For an investigation of all equipment controlled by your BMS you might like to consider a BMS Health Check or a BMS Audit. BMS Audits for West Mercia Constabulary “We commissioned The Green Consultancy to undertake an ongoing series of energy investigations, including BMS Audits, at our head office and various police stations. The service given and the treatment received has been excellent; a worthwhile investment to improve our energy performance. We are extremely satisfied with the results and are implanting the recommendations – and would recommend the Green Consultancy to our partner organisations.” Kim James, Force M&E Officer BMS Services for University of Worcester Following a BMS Health Check we provided a new strategy and full tendering support for a replacement BMS. These were some of the services delivered within a three year contract for energy management involving a consultant being on site for up to three days per week. "The Green Consultancy have proved to be adept at understanding the requirements of a complex organisation across an extensive estate and have worked with colleagues in the University of Worcester to help us better understand our priorities in relation to carbon reduction.