blazer hvac units

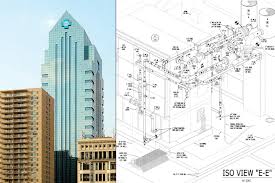

CENTER CITY OFFICE BUILDING Headquarters for one of Philadelphia’s largest employers, this single-tenant building is an icon of Center City’s skyline. Due to the age of this building, 48 50-ton package units in the building needed to be replaced. A small-size freight elevator made it impossible to move completed units to each floor. No work could be done during normal business hours. In addition, office partitions restricted the space in front of the small utility rooms on each floor. The client manages confidential documents, so security was a primary concern as well. Elliott-Lewis designed and developed a modular replacement unit specifically for this client application. Then Elliott-Lewis selected a manufacturer to build the units that would fit the freight elevators and allow fast assembly in the constricted area available. Sheet metal and piping were prefabricated off site. The equipment was tested before it left the factory, leaving the refrigerant charged.

Specified electrical connections were designed to be virtually “plug and play,” which reduced the field labor required to activate the electrical components in the equipment. A schedule was created to replace 8 units per year. Each replacement was executed over a single weekend. Work began at 5 PM with the removal of drywall around corridor openings and the breakdown of office cubicles fronting the corridor between the elevator and the equipment room. At the same time, the existing packaged unit was demolished and prepared for removal from the building. Working round the clock in shifts, the Elliott-Lewis team rigged and installed the new equipment; completed all field piping to connect the condenser, economizer and refrigerant lines; completed all power and control modifications to tie the new unit into the existing system, and reassembled the workstation and corridor openings. To insure that the work was completed by Sunday night, up to 60 Elliott-Lewis employees were utilized over the course of each 52-hour long coordinated operation.

The new equipment utilizes current technology, including R-410 refrigerant, variable speed drives for the direct drive fans eliminating the need for fan bearings and fan shafts, a robust direct digital control system networked to a front end, stainless steel condensate pan and coil supports and trim, and a cold water economizer coil. The system is 15 – 20% more energy efficient than the previous equipment.AC & Heating Services In Mechanicsville Serving The Greater Richmond Community At Blazer Heating and Air, we provide high-quality heating and air conditioning services throughout The Greater Richmond Community. important it is to have functioning heating and cooling systems in theAs such, it is imperative to have a reliable HVAC company on speed dial. technicians have the skill-set, experience, and resources necessary to handle all of your HVAC needs in a timely and effective manner. We will finish the job in accordance to your timeframe and budget.

ensure you are 100% satisfied with the finished product. We can help you maintain comfortable temperatures in your residential or commercial buildingWhether you are in need of system repairs or maintenance – we will get the job done right the first time. Emergency Services Available 24/7 Call To Schedule A Service1995 Chevy S-10 Blazer - 4.3 L Vortec V6 (vin W with PCM) - 230,000 miles original owner.

best split ac below 25000 india I changed my IAC Valve today, and coincidentally, my HVAC started blowing out of the defroster and floor no matter where I put the HVAC selector or fan switches.

2500 btu ac unitThis happens in all modes, AC, Heat, Vent, etc.

portable ac unit rental miami I don't see how this is related to my IAC Valve, but I put the old one back and the HVAC problem continues to be present.

I've had a similar problem in the past where it was intermittent and replacing the HVAC control switch fixed it. This time, the HVAC control switch was just replaced a couple months ago with a genuine AC/Delco part and it was working perfectly until today. Now, immediately after changing the IAC Valve, I can only get air to blow out the defroster and floor simultaneously. I did a lot of work on the car over the summer so I remember the recent vacuum readings. I checked the engine vacuum today and it's measuring the same as before. I also checked vacuum lines and intake manifold for leaks by spraying carb cleaner at these areas. There are no leaks and the engine is running fine... actually running better after changing the IAC Valve. What could be causing the HVAC to always blow out of the defroster and floor? I've ruled out the IAC Valve replacement as coincidence since swapping with the old IAC made no difference. Changing the IAC Valve on this vehicle involves two small screws and one electrical connector.

NO vacuum lines are involved with this or located nearby. I took out the dash panel and could hear hissing at the HVAC Control Switch. Unplugged the vacuum line assembly from the switch and measured vacuum on the source line. It's measuring the same as engine vacuum, so I can rule this out. Next, I manually applied a vacuum via pump to each line(s) while following the vacuum line schematic. I was able to get the heater, defroster, and vents to operate independently this way, ruling out all actuators. While the vacuum lines were hooked back to the switch, I was also able to get the Bi-level A/C, Defroster and Heater working properly by holding the connector on the switch a certain way to stop the leak. It is seemingly impossible to determine is whether the leak is coming from my "new" switch which was replaced last summer and working fine, or from the rubber connector assembly, which is factory original. Not sure how often these connectors fail or if they can even be replaced.