how to charge a ac unit using superheat

“INSPECTOR” 2 IN 1 ELECTRONIC / UV LEAK DETECTOR 45º ECCENTRIC FLARING TOOL KIT TUBE EXPANDING TOOL KIT (10 Head Kit) BALL BEARING TUBE CUTTERS 4-WAY BALL VALVE Digital Manifold + Data Logger Application Record and store up to 24 hours of data or 15 jobs. Displays Pressures, Saturated, Actual, Superheat and Subcool Temperatures. Clamp-on Thermocouple Connector displays Actual Temperature and Automatically Calculates Superheat or Subcool Temperature. Vacuum Sensor Cable displays Deep Vacuum. Ball valve design includes 3/8” bore through the block for increased flowTroubleshooting Roof Top RV Air conditioners RV rooftop air conditioners pack an amazing amount of cooling power into a unit that is lightweight, will run off 120 volt a.c.power, and will survive the rigors and vibrations of over the road travel. No matter which brand you have- Coleman, DuoTherm, Carrier AirV, Emerson Quiet Cool, or another- they all work on the same principal. To understand what can go wrong- let's first look at how they work, with some basic theory.

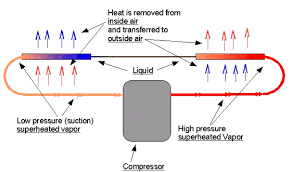

Like a refrigerator, an air conditioner operates not really by cooling the air, but rather by removing the heat from it, and dumping the heat outside. While this may seem like "nit picking", it is a very important concept in the operation of the unit, and vital to understanding how it works. The basic parts of an air conditioner are the sealed system- consisting of a compressor, a condenser, an evaporator, and the tubing used to tie it all together, the air moving system, consisting of a motor (only one in a typical roof top unit), and two fan assemblies- one to move air across the condenser, the other to move air across the evaporator. The sealed system contains the refrigerant, which in this case is R-22. We will start the heat removal process at the compressor- which, as the name suggests, compresses the refrigerant (which at this point is a vapor), at the same time adding heat to it. This "superheated" vapor then travels to the condenser (the "outside coils"), at which point the heat that was added by the compressor is removed (by the air flow from the condenser fan), cooling the vapor and causing it to condense to a liquid.

From here the liquid travels through a capillary tube, which regulates and restricts the amount that can flow through it, into the evaporator (the "inside coils"). The liquid refrigerant is then able to expand, but in order for it to expand, it has to absorb heat from the air being passed across it by the evaporator fan. As the refrigerant reaches the end of the evaporator, it has absorbed enough heat to vaporize it, and it turns into a superheated vapor. From here the suction side of the compressor pulls this superheated vapor in, compresses it, and the cycle starts over again. Basic compressor based refrigerant cycle From this explanation we can see that there are only a few requirements for a properly operating air conditioner. A properly designed system (which is a given), A properly charged system (we'll get to that in a bit), and adequate airflow over the condenser and evaporator, so that the evaporator can absorb enough heat, and the condenser can "dump" the heat outside.

A major part of the refrigeration process is the fact that it takes far more energy (heat) to change a substance from one state to the other- by state, I am talking about solid, liquid, or gas. When talking about air conditioners, we measure energy in the form of btu's. A BTU is the energy required to raise the temperature of one pound of water one degree farenheit- so to change one pound of 32° water to 33° water requires 1 btu, but..

home ac repair brownsville txto change one pound of 32° ice to one pound of 32° water requires 144 btu's.

bryant packaged ac unitsThe same principal holds true with the refrigerant in air conditioners- the heat is absorbed in the process of changing the refrigerant from a liquid to a gas.

jual ac portable karakter

If the unit is not properly charged, the change will take place too quickly, or not at all. But... the reason that I point this out is not to have people run out and have their service man "Check the Freon ®"- for two reasons- One- the system is sealed with the proper charge from the factory, and the proper charge is usually around 13 ounces of r-22. With this small amount of refrigerant, if there is a leak in the system, odds are that it will be empty, and not just "low". The other reason is that it takes a lot of care and a scale to weigh the refrigerant to properly charge one of these units. I'm not saying that it cannot be done with simple gauges, but the likelihood of getting a proper charge is very low- and 95% of the time, the refrigerant charge is fine. All right all ready- how do I fix it.. Website © 1998-2013 by Christopher D. Bryant, Bryant Services, LLC This website was built with HTML KickStart HVAC Check & Charge Instant mobile refrigerant charge calculator for HVACR applications.

The HVAC Check & Charge™ mobile app from Emerson Climate Technologies provides an on-site refrigerant charge calculator for air conditioning applications. Based on historic sliding cardboard charge calculators, this app allows contractors to easily calculate correct system refrigerant charge for R-22 or R-410A. Contractors can simply choose Subcooling, Superheat, or Airflow and enter the specified system temperatures along with the latent and sensible environmental loads. These values are then used to determine the proper system charge and whether the charge amount needs to be altered based on these conditions. Superheat Calculator (non TXV) For use with R-22 or R-410A Download the Check & Charge application for your Android™or iPhone® devices for FREE.The requested URL /forums/index.php?topic=2924.0 was not found on this server.Contractors: Questions & Answers Are your technicians providing the level of service your customers are expecting?

How can I be a quality contractor both in my customers perception and in reality? How can I be a true quality contractor? Can I be a quality contractor and still make money? Why do you require specific tools? How do we get involved in the CheckMe!® program? How can I increase my revenue and upgrade my customer base? We have a problem making sure our air conditioners installed in the winter are quality installations. Does Proctor Engineering have a solution? Strange as it may seem, most customers perceptions of quality have to do with appearances. CheckMe!® customer satisfaction reports repeatedly show that the appearance of the technician AND the use of booties are the numbers one and two positive comments by customers. The average customer is unaware of the nuances associated with air conditioners and many contractors take advantage of that by just making sure cold air blows out the vents. Therefore customers are very concerned that their contractor is trustworthy.

Contractors use many methods to provide ethical proof that they are trustworthy. The top level of ethical proof is the contractor’s proud participation with a reputable independent third party verifying the results of their technician’s diagnosis and work on that very customer’s AC. As you know there are many contractors that are good at faking the customer into thinking they are quality contractors. Making it the truth takes time, effort, and commitment. First of all, make quality the absolute value in your company. Don’t allow the technicians to do whatever they want on an air conditioner just because that is the way they have always done it. Insist that the diagnosis follows the manufacturers’ procedures. That means refrigerant charge is checked using Superheat and Subcooling, not just a rule of thumb look at pressures. (NOT THE TRADITIONAL BEER CAN COLD EITHER!) That means checking the airflow through the unit – at least using the temperature split method.

(NOT THE TRADITIONAL 20°F TEMPERATURE SPLIT!) That means on an installation both the inside coil and the outside unit are replaced (See exception) That means on an installation the evaporator and lineset are evacuated to 500 microns using a micron gauge. (NOT THE TRADITIONAL EVACUATION BY TIME – a waste of time – AND NOT WITHOUT A MICRON GAUGE) That means you evaluate the duct system beforehand to make sure it will work properly with the new unit (even if it did or did not with the old unit). That means you look at sizing the new system – maybe the customer wants it bigger, maybe it should be smaller. Quality means having the technician spend the time explaining what they found and what it means to the customer, not just flying out the door to the next job. This means that the technician must understand more about the air conditioner than the traditional technician knows. Good technical and people interaction training is essential for your technicians. If they do not know how to check charge using superheat and subcooling – that is a good place to start.

Quality means expanding what you are offering to the customer, which could include: Airflow Improvements, Duct Leakage Testing and Sealing, Unbalances in Air Delivery or Removing Zoning Bypasses, Control Upgrades for Climate Differences, High Efficiency Fan Motors, Information on Other Problems with their House such as an obviously under insulated attic, leaky house, etc. Quality means continuously checking that your company and technicians are improving and following the new procedures you put in place. Correct any backsliding and move ahead. Quality means tracking customer satisfaction and technician performance. Don’t just accept reports that “everything is fine”. Regularly inspect a few of your own company’s jobs. Of course, but you may need to change some of the things you do now. It may mean that you have to “walk away” from some jobs because the customer says they want a quality job – but they really don’t want it enough to pay for it. You may have to walk away from a job where the customer insists on having it done wrong.

It may mean that some of your technicians may leave – they may not want to change for various reasons. Don’t worry about that, they will eventually be replaced by a technician who ends up being a larger asset than the one who leaves. It may mean that your technicians may need to upgrade some of their tools. You will make more money by reducing callbacks and increasing referrals to the type of customer you want – one interested in a quality job they can have faith in and are willing to pay for. You will make more money because you have the trust of your customers and the friends of your customers. When you tell them the potential improvements they can make in their system they will believe you because you're telling the truth. Since our trainers and inspectors work directly with technicians every day, we see what gets them into trouble and lowers quality. We have tested many tools and find that some work well, while others do not. We continuously upgrade our list with new equipment as we can confirm their performance.

For years we have been doing trainings with technicians and testing the accuracy of their analog refrigerant gauges. We have found over 75% of all the analog gauges used by these technicians are inaccurate. This led us to conclude that we needed to make a change. Starting in 2009, we began recommending digital gauges, and now insist on them in all our new programs. As a result, the rate of failures on inspection has fallen significantly. Each CheckMe!® technician must receive hands on training and be certified in the program. This entails signing a contractor agreement, completing the training course, and submitting 10 successful CheckMe!® diagnostics. You can also sign up for more information. First of all, let’s remember that we want more customers that will pay for a quality product, not just more customers. A customer that will pay for a quality product will give you fewer headaches and higher revenue per job. One way of increasing your customer base is to change from a standard low price “Spring or Fall Special” to providing a unique upgraded diagnostic using the CheckMe!