hvac unit life expectancy

You are here » Central Air Conditioning Figuring Out the Life Span of Your Air Conditioner During our hot, humid Indiana summers, a reliable air conditioner is a necessity to keep your home cool and comfortable. If your A/C doesn’t seem to work well anymore, you may be wondering how long it will last. There are easy to recognize signs that can help you figure out your air conditioner’s expected life span, and whether it’s time to talk to your HVAC contractor about replacement. Telltale Clues to Your Air Conditioner’s Life Span The A/C’s age – The average air conditioner life span is roughly 15 years. If yours is over 10 years old, you can expect to see a steady loss of cooling capacity and efficiency. Older equipment is more prone to breakdowns too, so necessary repairs are more frequent. By replacing your A/C before these problems escalate, you can save on energy and repair costs and avoid an inconvenient mid-cooling-season equipment failure. Poor humidity control – As air moves across the evaporator coil of a well-functioning air conditioner, excess moisture is drawn out and then expelled outdoors via the condensate drain.

As an A/C gets older and less efficient at moving air, it’s not able to dehumidify a home as effectively. If you’re experiencing uncomfortably high indoor humidity levels, mold and mildew issues, musty odors and/or damage to wood trim, ceilings and paint, it can be a clear sign that your older A/C is ready for retirement. Excessive energy costs – Are your energy consumption and seasonal utility costs rising year after year even though your day-to-day cooling needs haven’t changed? If so, the equipment may be reaching the end of its service life. If it’s an older model, the A/C’s seasonal energy efficiency ratio (SEER) may not provide optimal efficiency either. Replacing an older 10 SEER unit with an new 16 SEER model can cut 60 percent from your annual energy costs. Opting for an efficient Energy Star-rated unit can boost those savings by an additional 15 percent. If you need help figuring out your air conditioner life span, please contact us today at Meyer’s. We’ve proudly served Griffith, Highland, Gary and the surrounding areas since 1951.

468.8323 Home inspection report. Upon completion of each home inspection for compensation, the home inspector shall provide a written report prepared for the client. (1) The home inspector shall report: (a) on those systems and components inspected that, in the professional opinion of the inspector, are significantly deficient or are near the end of their service lives; (b) if not self-evident, a reason why the system or component reported under paragraph (a) is significantly deficient or near the end of its (For a comparison of service life expectancies in other areas of the U.S., see InterNACHI's Estimated Life Expectancy Chart for Homes.) ADHESIVES, CAULK & PAINTS FASTENERS, CONNECTORS & STEEL 15 to 25 (if installed) INSULATION & INFILTRATION BARRIERS MOLDING, MILLWORK & TRIM PLUMBING, FIXTURES & FAUCETS Toilets, Bidets and Urinals Radon systems have but one moving part: the radon fan. SIDINGS, FLASHING & ACCESSORIES

Note: Life expectancy varies with usage, weather, installation, maintenance and quality of materials. This list should be used only as a general guideline and not as a guarantee or warranty regarding the performance or life expectancy of any appliance, product, system or component.

rheem ac units 2 ton Make your own clean copy of this chart.

portable air conditioning units melbourneAs warmer weather taxes aging air-conditioning systems, the decision whether to repair an older rooftop unit or replace it with a newer, higher efficiency system may loom large for some commercial property owners.

cost of hvac per m2Most light-commercial HVAC products are for a life expectancy of 15 to 20 years. However, factors beyond the control of the original equipment manufacturer dictate the actual reliability and cost effectiveness of operating the equipment during its useful life period.

That’s why it’s important to carefully examine each piece of equipment before reaching a decision to repair or replace a system. Understand the History of Your SystemA careful examination begins with the collection of all available information regarding the system, including records of the original installation, periodic maintenance, and repairs. If you do not have this information, contact servicing contractors and let them know you are evaluating your equipment to determine whether or not you will be replacing it. Cooperation will usually follow, and you will have the opportunity to “size up” the contractor for consideration when doing future maintenance, repairs, or replacement.If you do not have a file on each piece of equipment, start one. In addition to the records you collect, be sure to include the manufacturer’s model and serial number, individual unit or site reference numbers, installation and operating instructions, warranty information, and factory- or contractor-backed service and maintenance agreements.

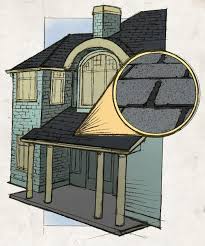

Overall appearance of each unit will provide valuable information about the quality and attention to maintenance provided the unit. Inspect the equipment (or have a qualified technician perform the inspection), following the manufacturer’s instructions and safety warnings before removing any access panels.The cabinetry should be intact and fastened properly to minimize any air (or weather) leakage into or out of the unit. Filters, too, should be clean. Clogged or restricted filters reduce a system’s efficiency markedly, increasing the internal negative air pressure and pulling dust, dirt, and debris into the unit’s air circulating system. Check the condition of the coils as well, looking for evidence of dirt, debris, or physical damage to the coils. Bent, damaged, or restricted coils restrict air flow, reducing unit efficiency and increasing operating costs.Arrange for a professional contractor to inspect each unit to assess its operating condition. If you can tie this to a periodic maintenance or repair call, you will save some expense.

The inspection should include a complete operating review of the and portions of the equipment and an assessment of the airflow, temperature rise, and temperature split to be certain they are within the manufacturer’s specified ratings. Be present for the inspection and request that the technician review the findings with you, including the identification of problems and recommendations and quotes for corrective actions. Include this information in the unit files you have started.Review the Information You Have CollectedAt this point in the evaluation process, you likely have learned a lot about each system. As you review the information you have gathered, determine and confirm the applicable manufacturer and contractor-supported warranty coverage that remains on each unit. Based on the records you have and inspections conducted, assess the condition of each unit. Equipment improperly maintained and serviced is likely to be less reliable and less efficient, resulting in increased operating costs and premature failures and repair costs.

Consider the age of the unit, warranties or service contracts that apply, and the condition of the unit. Has it been well-maintained and what repairs are needed in the short term and the long term?Make the Decision to Repair or ReplaceStudying current operating expenses as well as projected repair and operating expenses better equips you to make the decision to repair or replace existing equipment. Compare these expenses to the operating costs of new, high-efficiency equipment. Most manufacturers can help you make this comparison by estimating operating costs based on unit efficiency and local utility costs. In many cases, if your equipment is aged, new high-efficiency replacements will provide significant utility savings that can be factored as a “payback” in a decision to replace.A firm quote from your contractor will help you estimate the future costs associated with restoring a unit’s operating performance. Finally, as you make your decision to repair or replace, consider applicable utility rebates for the installation of high-efficiency equipment.

Your local utility can provide rebate information that applies to your area.You should also consider potential savings that new equipment warranties will provide compared to out-of-warranty repair estimates. The purchase of extended warranties and scheduled maintenance programs offer additional savings worthy of your consideration. Often these warranties can be negotiated into the initial purchase price for new equipment and offer an affordable approach to future maintenance and repairs.Select a reputable local contractor who will offer future support or backup of their workmanship. Work to define a maintenance and monitor program for the existing or new installation. This program should cover all aspects of the equipment, be performed regularly with accurate recordkeeping, and include basic system performance measurements to assure each unit remains in peak operating condition.Be certain to keep accurate records. These records will help you estimate operating expenses and, in the event of future problems, guide your contractor in proper repairs.