wiring diagram for goodman ac unit

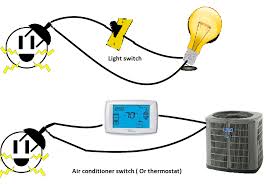

If you have found this site, chances are you are looking for wiring diagrams. Wiring diagrams are always published by the manufacturer and so the best source to get them is from the manufacturer. Usually they come with the owner's manual, but always should be attached to the door of the electrical panel.Below are some sample wiring diagrams from a few common manufacturers. Most heat pump wiring diagrams follow the same concept. So if you are looking to understand the concepts, the diagrams below will help. Heat pump wiring is subdivided into two sections:Power wiring uses high voltage. Most of it is factory-wired...so it is not too complicated. Follow all local and national electrical code when preparing and installing the wiring and over-current protection.UL 1995 is a standard developed by UL that most HVAC manufacturers follow. In fact, even if the unit is not UL listed (may have other listings like CSA, TUV, etc.) the manufacturer should have followed UL 1995.UL 1995 contains two very important calculations.

These calculations are essential to understand when design any heat pump electrical system: This number is a guide determining what size power wire to use. The calculation goes like this:MCA = (1.25 x largest motor FLA) + all other electrical load FLAs Note: FLA (full load amps) The MOP (maximum over current protection) is the largest fuse or circuit breaker size desired for the application. This calculation is:MCA = (2.25 x largest motor FLA) + all other electrical load FLAs This is probably the most complicated part of the heat pump. Each manufacturer sets up their controls differently. So a technician must become familiar with each manufacturer.Consult the wiring diagram specific to your heat pump for details on how to wire your unit. Back to Heat Pump Troubleshooting Use the parts lists on home page to identify the correct part number. If the part is not currently listed within the website use the CONTACT US feature and customer service will promptly reply with price and availability.

REPLACEMENT PARTS FOR FURNACES, AIR CONDITIONING AND AIR HANDLERS MANUFACTURED BY GOODMAN Goodman products, including the GMC and Janitrol brands are made with the best components available. Like all household appliances, furnaces, air handlers and air conditioning equipment eventually wear out. However, it's possible to prolong the life of a your equipment by following the proper care instructions that come with the units.

car ac repair kalamazooTo get longer life from your Goodman furnaces, air conditioners and heat pumps, when a higher stress component such as a gas valve, air switch, blower motor, blower wheel or ignitor fails, you can purchase genuine replacement parts from one of the country's leading wholesalers.

home ac repair clovis caWe also stock numerous reset switches required for the latest models.

hvac blower motor lowes

ELECTRICAL ITEMS AND CONTROLS ARE FACTORY TESTED AND ARE NOT RETURNABLE PARTS LISTS - GOODMAN SPLIT SYSTEM AIR CONDITIONERS Goodman Manufacturing Company, L.P. ("Goodman") produces a complete line of residential and commercial air conditioning and heating equipment at its three modern, high technology factories, totaling over 1,200,000 square feet in Houston, Texas, Dayton and Fayetteville, Tennessee. Goodman's equipment is sold through a worldwide network of independent distributors and installers who are dedicated to uphold the company's high standards of quality. The Goodman philosophy: Be the highest quality, lowest cost producer of heating and air conditioning equipment in the world. GMC 202400410731 FAN MOTORGMC 20511018 / 0131M00666 END BELL FC100A1029 16 X 25 X 5 FILTER GMC 0121F00051DGS BASE PANGMC 0130F00038 PRIMARY LIMIT LIGHT BLUE 120º GMC 0130F00070 PRESSURE SWITCH GMC 0130F00100 PRESSURE SWITCHGMC 0131M00414S BLOWER MOTOR, 1/2 HP PROGRAMMED X13GMC 0131M00532S MOTOR, 3/4 HP PROGRAMMED

GMC 0131M00549S MOTOR-1/2 HP PROGRAMMEDGMC 0150G00000P BLOWER WHEEL 9 X 8GMC 0231K00009A BLOWER MOTOR 1/2 HP PROGRAMMED GMC 0231K00044 BLOWER MOTOR 1 HP PROGRAMMEDGMC 10123517 MANUAL RESET LIMIT SWITCHGMC 10123534 MANUAL RESET LIMIT SWITCH 220ºF GMC 10135601 RELAYGMC 11119203S BLOWER MOTORGMC 201100290011 CROSS FLOW FAN GMC 201100300514 AXIAL FLOW FANGMC 201300730954 PROGRAM CHIPGMC 201337590002 CONTROL BOARD GMC 20170808AS FLUE COLLECTOR ASSEMBLYGMC 20170901AS FRONT COVERGMC 20170902AS FLUE COLLECTOR ASSEMBLY GoodmanParts.net is an online store from an independent wholesaler and not an outlet from the manufacturer themselves. var _qevents = _qevents || var elem = document.createElement('script'); elem.src = (document.location.protocol == "https:" ? " var scpt = document.getElementsByTagName('script')[0];

Describe your project and send it out to our top rated service providers. No membership or credit card requiredGet StartedNo thanks, I'm not quite ready.The best hard start kit - don't be fooled by 2 wire kitsWorked for reducing the lights dimming when AC turns on, but capacitor is "one size fits most".Saved me a lot of moneyRecommended even for newer unitsEasy install.Wonderful product saved me $10,000.00!Easy to installGood upgrade for any condensing unitEasy to install and it seems to workEasy Hookup←Previous...Get fast answers from reviewers See all 21 answered questions Customers also viewed these itemsCompressor Saver Hard Start Capacitor Model CSR U293Compressor Saver Hard Start Capacitor Model CSR U378Supco SPP6 Hard Start Kit31Supco SPP6, Relay Start Capacitor 120-288V42Need customer service? It’s been said that hackers are enamored with complex networks. In the 60s and 70s, the telephone network was the biggest around, singing a siren song to an entire generation of blue-boxing phone phreaks.

I started a bit closer to the house. As a child I was fascinated by the heating system in the basement of our home: a network of pipes with a giant boiler in the middle. It knew when to come on to provide heat, and when to kick on for hot water. I spent hours charting the piping and electrical inputs and outputs, trying to understand how everything worked. My parents still tell stories of how I would ask to inspect the neighbors heating systems. I even pestered the maintenance staff at my nursery school until they finally took me down to see the monstrous steam boiler which kept the building warm. My family was sure I would grow up to be a Heating Ventilation and Air Conditioning (HVAC) tech. As it turned out, electronics and embedded systems were my calling. They may not have been too far from the truth though, as these days I find myself designing systems for a major manufacturer of boiler controls and thermostats. Recently a house hunt led me to do some HVAC research on the web.

What I found is that HVAC techs have created a great community on the internet. Tradesmen and women from all over the world share stories, pictures, and videos on websites such as HVAC-Talk and HeatingHelp. Heating Ventilation and Air Conditioning is one of the mechanical trades. Being an HVAC service tech isn’t a glamorous position. However, if you wake up on a cold winter morning with no heat, he or she can be a life saver. For folks living in colder climates, this is often a literal statement. Carbon monoxide, freezing temperatures, and fire are just a few of the ways a malfunctioning heat plant can wipe out a family. One of the most interesting jobs the HVAC service tech goes on is the service call. This is where they get to be the troubleshooter. It could be no heat on an oil-fired boiler in a home, or no cooling on a rooftop commercial air conditioner. Their task is to get the system running, and to do it safely. Some systems are beyond repair though. No tech wants to leave a family without heat, but if a system is creating a dangerous condition, such as leaking carbon monoxide into the home, there isn’t really a choice.

For those that can be repaired, techs have come up with an amazing array of hacks to get systems up and running safely. The best way to find out about these tricks and hacks is to watch some techs at work. Thanks to the wonders of technology, we can now do that without climbing up on a hot roof or crawling through a dusty basement. An excellent community of techs has formed on YouTube. Techs like [Steven Lavimoniere], [Halligan142], and [Stephen Rardon] pack their cameras along with their wrenches and torches so we can ride along on their calls. It takes a special kind of tech to record and post videos of their work. Any mistake, unsafe practice, or “half fix” will be picked apart in the comments. YouTube commenters are relentless, so folks making videos are very good or very brave or both. The channels also outline how different work can be. [Halligan142] does a lot of work on small commercial systems. He can often be found on rooftops working on gas-fired heating systems, and AC units.

Definitely check out [Halligan142’s] series on machining, as well as building a proton pack for Ghostbusters cosplay. [Stephen Rardon] does a mix of residential and commercial work in North Carolina. Many of his days consist of servicing heat pump systems. Steven also shows off many of the newer tools available to the industry. Rather than the old gauge sets to measure refrigerant pressure, he uses a system called iManifold. Bluetooth sensors attach to the refrigerant lines as well as the air feed and return. The entire system’s performance can then be viewed on an Android or iOS phone or tablet. [Steven Lavimoniere] hails from North Dartmouth, Massachusetts. His geographical area uses a lot of oil-fired hot water heating systems. That means he has to be a master plumber as well as an HVAC tech. His videos show how nasty oil service can be, especially on systems that haven’t been serviced in a few years. [Steven] also uses new electronic test equipment. His Testo combustion analyzer displays oil and gas system efficiency, and even allows him to print a permanent record of the results.

This is a lot better than older systems like the Fyrite. The old systems determined CO2 and oxygen levels by measuring the volume change in a liquid which absorbs each gas. Efficiency calculations are then performed with a slide rule based upon the change in liquid volume and exhaust temperature. The liquids were composed of some nasty chemicals such as mercury chloride (HgCl2) and chromium (III) chloride hexahydrate, which I’m sure techs like [Steven] don’t miss. You have to love Steven’s accent too. I was brought up watching episodes of This Old House, so the Bostonian accent is a perfect pairing with working on old homes and their systems. The commenters watching these channels are more like hawks than your run-of-the-mill YouTube trolls. Many of them are HVAC techs themselves. These folks are often speaking with the voice of experience. Just as electrical engineers have to deal with bad hardware design, or software engineers deal with tangled legacy code, HVAC techs often have to cope with poorly installed systems, bad service, and years of neglect on heating and cooling systems.

Techs have come up with their own vocabulary for the types of problems they run into. The “Run Cap Bandit” is someone who throws a new start/run capacitor on a system with a failing compressor. HVAC-talk, a popular website for techs, has an entire section dedicated to photos of the types of issues field techs run into appropriately called The Wall of Shame. Inside you’ll find scenes like this one – a water heater with an exhaust made of PVC waste pipe. It’s never a good idea to vent 300+ degree F gas through plastic. One question that often comes up is “can I work on my own heating or cooling system?” Here at Hackaday we are all about doing it yourself – but there are limits to what even we will try. While writing this article I took an informal poll of the writing and editing staff. Many of us have made repairs to our own systems – such as brazing joints on an evaporator coil, or replacing a thermocouple on a gas system. I myself have repaired broken pipes on my hydronic system, and have changed simple things like a clogged oil filter.